Addressing Today’s and Tomorrow’s Multiphysics Simulation Challenges

This resource discusses how OMNIS™, with its breadth of CFD technology behind, solves the most complex fluid flow challenges for automotive design, while at the same time reducing engineering and solving time, in a fully streamlined easy-to-use collaborati

March 27, 2020

The automotive industry has been using CFD tools in the design and optimization processes of all parts of the vehicle, from external aerodynamics to noise reduction to thermal management to internal combustion etc. Most often within the design process, all of the above are combined together in what is called a virtual prototype to allow optimizing the vehicle as a system.

The physics behind the various applications are however quite often very different, which translates into the need of having dedicated technology for each specific application.

As a consequence the designers, scientists or engineers are often using a large number of various CAE codes and software tools with different interfaces (GUIs), data set-up, structures and formats, each of them focusing on their specific discipline, with no or poor connection between them. A more global approach to the whole CAE workflow for a multidisciplinary design and optimization loop has become an absolute necessity for these users.

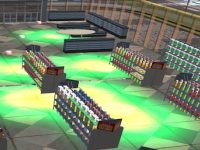

This is where OMNIS™ comes in: an end-to-end CAE environment with dedicated tools to solve each step of the simulation process quickly and efficiently. OMNIS™ gives global approach to the whole CAE workflow from design to results analysis, driven by the user through an ultra slick user-interface, or controlled automatically with the Python API or even by the optimization module.

Its unified user-interface reduces the user’s learning process and its consistent datastructure avoids slow file conversion and annoying corruption errors. The unique OMNIS™ framework enables tools to communicate with each other within one workflow, while its multiple solvers give access to a broad range of technologies for solving any fluid/acoustic flow problem, with the added flexibility of being able to plug in in-house or opensource solvers and tools via the API.

Fill out the information below to download the resource.

Latest News