June 28, 2021

Small devices that require high precision, high resolution, and high accuracy are all around us. From the electronic connectors in cellphones to the tiny valves in medical pumps, these devices aren’t just small in size; many have small features with significant complexity.

Historically, micro CNC machining and micro injection molding were the only way to make precise parts like this. Both methods require paying for and waiting for tooling, which adds project costs and lengthens time-to-market.

Additive manufacturing, or 3D printing, doesn’t require molds or tools. Moreover, it can reduce the time from concept to prototyping to low-volume production. Yet most 3D printers aren’t able to make small parts with high precision, resolution, and accuracy. Now that’s all changing. Thanks to PμSL technology from Boston Micro Fabrication (BMF), you can 3D-print small parts with 2 μm resolution and +/- 10 μm accuracy at scale.

What is PμSL?

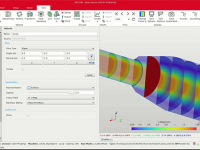

BMF’s 3D printers use projection micro-stereolithography (PμSL), a form of stereolithography (SLA) that incorporates a DLP® light engine, precision optics, motion control, and advanced software. SLA produces parts in layers using a photochemical process.

A photosensitive liquid resin is exposed to light so that polymeric cross-linking and solidification occurs. With PμSL technology, a flash of ultraviolet (UV) light causes the rapid photopolymerization of an entire layer of resin. PμSL technology supports continuous exposure for faster processing.

Fill out the information below to download the resource.

Latest News