May 5, 2022

As components, parts, devices, and products are expected to last longer, perform better, be updated faster, and cost less, engineers are faced with increasingly complex design challenges that were unimaginable only a decade ago.

Adopting a modern workflow in the product development cycle liberates designers and engineers from legacy software constraints and hardware limitations resulting in less physical prototyping, mass-customized products, and budget optimization.

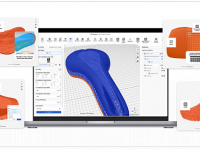

In this whitepaper, specialists from Onshape, SimScale, and ESTECO cover the implementation of a design-simulate-optimize workflow relying on tools built on the latest cloud computing and optimization technologies, applied to the design of a centrifugal fluid pump.

Fill out the information below to download the resource.

Latest News

CRP USA Elevates Wheelchair Racing Gear for Paralympics Champion

Using Windform XT 2.0 material and selective laser sintering, CRP USA created racing agloves that are lighter, more durable, and offer...

Altair Names Winner of the 2023-2024 Altair Global Student Contest

Student winner used Altair Inspire to slash his team's Shell Eco-marathon vehicle suspension weight by 41%, according to Altair.

Hexagon Unveils Digital Solution to Optimize Factories

By connecting asset digital twins to an accurate and up-to-date Digital Factory, companies can plan and operate more productive, flexible...

Hyperganic Launches HyDesign

Software reportedly made to democratize 3D-printed lattice design.

Eagle Point Software Partners with SOLIDX to Expand Reach in UK

Collaboration brings Pinnacle Series to SOLIDWORKS users in the UK.

Ohio R&D Center to Advance National Security Propulsion Technology

Purpose of center is to advance additive manufacturing and materials development technology for liquid rocket engines and solid rocket motors.

All posts

New & Noteworthy

New & Noteworthy: Fast, Flexible and Scalable Simulation – In the Cloud

Ansys Access on Microsoft Azure enables seamless deployment of industry-leading simulation tools...

New & Noteworthy: Safe, Cost-Effective Metal 3D Printing - Anywhere

Desktop Metal’s Studio System offers turnkey metal printing for prototypes and...

New & Noteworthy: Direct Neutronics Analysis on CAD

Coreform Cubit 2023.11 workflows enable neutronics directly on CAD for next-generation nuclear energy...

New & Noteworthy: Agile Engineering Collaboration

Authentise Threads is a new software tool for distributed communications and project...