August 30, 2021

Miniaturization is increasing across industries, as the need for very small and very complex components increases in consumer electronics, medical devices, MEMS, life sciences and many other industries.

At the same time, manufacturers are searching for new approaches to creating these highly detailed but small products and components. Demand is high for small, precision parts, but traditional manufacturing processes are slow and expensive.

Download this new Making the Case guide to learn more about emerging technology that provides the flexibility of additive manufacturing at a micro scale, but at a price point that is affordable for many production scenarios.

Download today

Latest News

Next-Gen: Growing Green Space Access via Mobility

Student Competition Profile: Otis Worldwide’s “Made to Move Communities” Competition

Securing Design IP in Distributed Manufacturing

Decentralized production models increase security and risk exposure of standard design intellectual property and additive manufacturing process parameters and recipes.

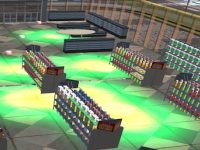

Digitally Designing the Factory of the Future

Artificial intelligence also plays a role in building an efficient, economic plant layout for optimal operations.

Vectary API Brings Product Digital Twins to Life

The new offering enables companies to integrate digital twins for immersive 3D experiences, enhanced decision making, and real-time product control.

3D Printing at the Crossroads

Additive manufacturing events revealed a state of the industry that is facing economic obstacles.

Altair Acquires Cambridge Semantics

Cambridge Semantics is a modern data fabric provider and creator of one of the industry’s analytical graph databases

All posts

New & Noteworthy

New & Noteworthy: Safe, Cost-Effective Metal 3D Printing - Anywhere

Desktop Metal’s Studio System offers turnkey metal printing for prototypes and...

New & Noteworthy: Direct Neutronics Analysis on CAD

Coreform Cubit 2023.11 workflows enable neutronics directly on CAD for next-generation nuclear energy...

New & Noteworthy: Agile Engineering Collaboration

Authentise Threads is a new software tool for distributed communications and project...

New & Noteworthy Product Introduction: Enterprise VR Headset

Lenovo ThinkReality VRX has an immersive display works with virtual, augmented and...