Creating Wireless Modular Robots with High-Precision 3D Printing

The pursuit of advanced robotics is motivated by the necessity for adaptable and configurable systems. Formerly, robots have been encumbered by stiff designs, curbing their suitability in frequently varying conditions.

3D Printed Modular Cubes

Additive Manufacturing News

Additive Manufacturing Resources

Boston Micro Fabrication

Latest News

July 13, 2023

The search for versatile and adaptable systems is a driving force in robotics research. Traditional robotic systems rely on fixed structures, limiting their adaptability in dynamic environments. If robots could reconfigure their form and function on demand, they become more useful in various settings.

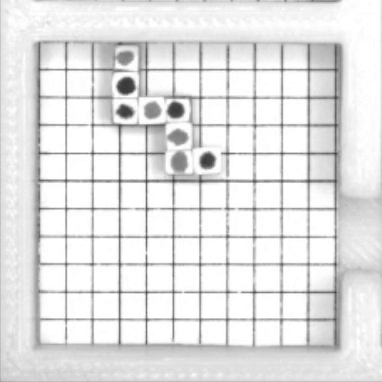

While completing his Ph.D. in mechanical engineering in the Biological, Actuation, Sensing, and Transport (BAST) Laboratory at Southern Methodist University, Anuruddha Bhattacharjee set out to engineer modular robotic cubes equipped with magnetic connectors and embedded magnets, enabling them to interact and form various configurations. These modular robotic cubes were manipulated wirelessly using an external magnetic controller, opening new avenues for milli-/microscale reconfigurable robotic systems.

Designing the Modular Robots

Dr. Bhattacharjee needed to design and fabricate functional modular cubes with magnets embedded in their face that could be manipulated with an external electromagnetic controller. The cubes had 2mm edges with ten 300µm holes for the embedded magnets. For the cubes to operate properly, they needed precise micro-holes in the faces for embedding the magnets. The team turned to high-precision 3D printing with projection micro stereolithography (PµSL) to fabricate the cubes with the precise micro-hole.

Wirelessly Controlling the Cubes

Once the functional modular cubes were fabricated with embedded magnets, they were tested in an electromagnetic triaxial Helmholz coil setup for controlled self-assembly, on-demand disassembly, and reconfiguration tasks. The precise motion of the individual cubes is crucial for the successful self-assembly of the modular robots. The precise motion is dependent on the accuracy of the cube’s fabrication. Most standard 3D printers do not provide the required precision and accuracy. Using the microArch S140, Dr. Bhattacharjee could quickly fabricate the cube with accurate dimensions.

“Within just two weeks, we received our 3D printed parts. The microArch S140 accurately produced the precise dimensions based on our design file. The BMF team’s effective communication enabled us to accelerate our research process and obtain results earlier than anticipated. Given their efficient communication, product delivery, and responsiveness, we highly recommend BMF as a reliable partner for long-term collaboration.”

The Future

The reconfigurable modular robots can be wirelessly manipulated with an external magnetic controller and self-assembled or disassembled on command. The small-scale cubes fabricated with PµSL technology and the availability of biocompatible materials opens possibilities for using magnetic modular robots for surgical tools and biomedical applications.

More Boston Micro Fabrication Coverage

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News