The Importance of Machine Tolerance to Achieve Exacting Results in 3D Printing

This paper will discuss the tolerances and the effect that machine or mechanical tolerance of the equipment has on overall part tolerance.

February 13, 2023

Accuracy & Precision

Before going into details, we should quickly highlight the difference between accuracy and precision, and why these are important. Accuracy refers to the ability to achieve the desired dimensions; for example, a 10mm pillar when printed is 10mm. Precision refers to how close the measurements of the same item are to each other. When looking at the graphic below, it is easy to see that the best outcome for a 3D printed part is high accuracy and high precision.

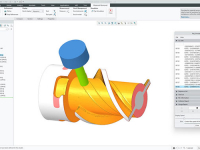

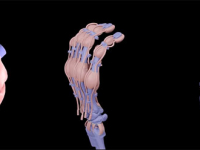

The ability to hold high accuracy and precision in additive manufacturing depends on multiple factors. Resolution of the data coming from the software plays a part. Behavior of materials (shrinkage or expansion) plays a part. Choreography of slicing and layer thickness plays a part.

In the end, all these factors are limited by the machine tolerance of the actual device being used. If machine tolerances are “loose”, the ability to hit tight dimensions is limited. If machine tolerances are “tight”, there is a greater ability to meet high accuracy and precision.

Fill out the information below to download the resource.

Latest News