March 30, 2021

After years of primarily being used to create prototypes and models, 3D printing technology is increasingly proving its worth for the production of end use parts across a wide variety of industries.

One important application for the technology has been the creation of spare parts, jigs and fixtures in a production environment. There is a high cost associated with maintaining an inventory of these parts for equipment that may be in service for years or even decades. 3D printing allows companies to create these parts on demand.

We asked the experts at Ultimaker how their 3D printers are used to create end use parts. In this Insider Q&A, see how Ultimaker customers are leveraging 3D printing to improve their manufacturing operations.

Download today

Latest News

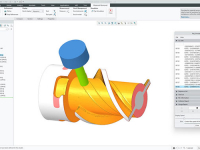

PTC Releases Creo v11, Updates Creo+

This launch enables engineers to enjoy enhancements for electrification, composites, model-based definition, simulation-driven design and manufacturing, the company says.

CADENAS Announces Membership in Industrial Twin Association

The IDTA is the first point of contact for all aspects of the standardized digital twin.

Hexagon Announces Leadership Appointments

Hexagon Asset Lifecycle Intelligence Division appoints senior leadership.

Ingersoll Rand Leads $19M Financing Round for Inkbit

Inkbit will use funding to advance to multifunctional additive manufacturing.

CAD Users Embrace Hybrid Modeling

Subdivision modeling gaining ground in production phase surface modeling.

ESTECO International Users’ Meeting Announces Agenda

The early June meeting, to take place in Italy, includes keynotes from Toyota, Eaton and more.

All posts

Related Topics

New & Noteworthy

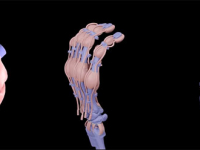

New & Noteworthy: Safe, Cost-Effective Metal 3D Printing - Anywhere

Desktop Metal’s Studio System offers turnkey metal printing for prototypes and...

New & Noteworthy: Direct Neutronics Analysis on CAD

Coreform Cubit 2023.11 workflows enable neutronics directly on CAD for next-generation nuclear energy...

New & Noteworthy: Agile Engineering Collaboration

Authentise Threads is a new software tool for distributed communications and project...

New & Noteworthy Product Introduction: Enterprise VR Headset

Lenovo ThinkReality VRX has an immersive display works with virtual, augmented and...